The Basics

Nearly every commercial kitchen is required to operate and maintain a grease trap in order to prevent sewage blockages. Grease traps primarily deal with fats, oils, and greases (FOG) that are produced during cooking, baking, frying, dish washing, or any other culinary operations.

Even with procedures in place to minimize the number of FOG materials that are washed away in the kitchen, preventing all of them from going down the sink is effectively impossible. Fortunately, grease traps exist for this very purpose: to trap and intercept FOG before the greasy culprits make it to the main sewer. They can be anywhere from under the sink to under the back parking lot, and they vary in both size and flow.

Though the job seems relatively simple, there is a veritable swarm of different models, sizes, and efficiencies that grease traps can have. When choosing one for your restaurant, it’s important to consult with a manufacturing professional as well as your local commercial kitchen regulations. Every kitchen’s needs are different, and laws regarding size and placement vary from state to state.

Grease Trap Design

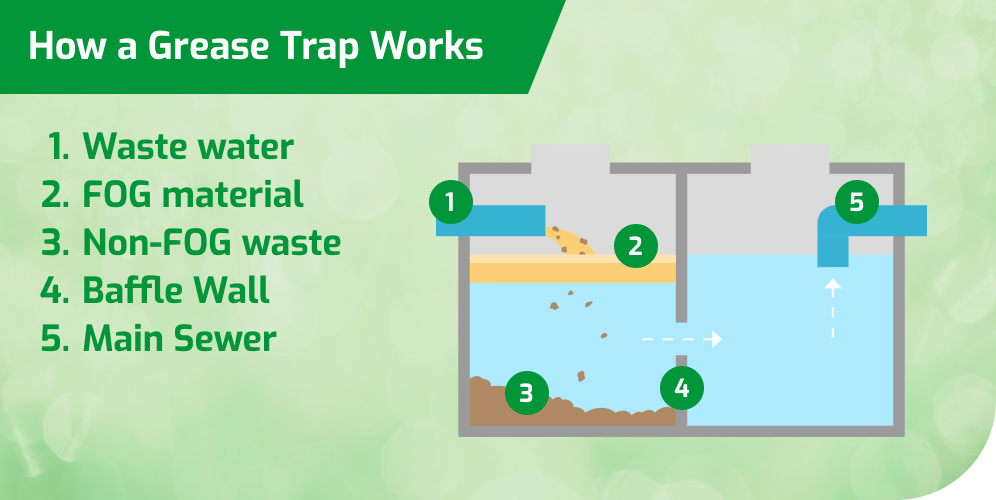

While different terms may be tossed around enough to become quickly confusing, rest easy in the fact that all grease traps operate through the same basic method. Traps that remove FOG material from water rely on the difference in density between water and grease.

There’s a good chance you have seen this difference in action. If you’ve shaken up a tasty balsamic vinegar and oil dressing, you’ll know that the two don’t stay friends for long. Even after vigorous mixing, they’ll stubbornly separate into their own layers. Grease traps’ designs take advantage of this inevitable separation.

Because the oils, fats, and greases will always rise to the surface of the water, a tube that dips below the water’s surface can pull out water that has separated from FOG liquids. Sludge and other non-FOG food waste will quickly sink to the bottom.

Comparing salad dressing to kitchen liquid waste might not be the most pleasant of parallels, but the basic premise is true for both.

Grease Interceptor Vs. Grease Trap: What’s The Difference?

While people may use the term “grease trap” (or “grease pit”) to describe any technology that keeps FOG materials from causing problems, it does have a specific definition. There are some slight variations that it helps to be aware of when you are purchasing a grease management system.

Fortunately, there are only two major distinctions: grease traps and grease interceptors. The former is classified as having a flow of less than 50 gallons per minute, and the latter is classified by having a flow of greater than 50 gallons per minute. That’s pretty much it: grease interceptors have a flow greater than 50 gpm, and traps include anything less. You’ll notice this definition does not necessarily determine size, as much as it does speed. Due to this, the actual size of a grease trap or interceptor can vary, while the flow is the determining factor as far as naming conventions go. Whichever your restaurant needs is determined on a case-by-case basis, and might also change with your municipality's guidelines.

Grease Trap Cleaning

As you might suspect, grease traps, as machines that perform exclusively dirty work, do need to be cleaned periodically. Regularly emptying them of both grease and sludge is essential to keep the technology working right. Some FOG materials may decompose naturally, but the process is too slow to be timely. As such, the trap needs to be evacuated every once in a while, no matter how well you use it. Grease trap cleaning frequency is based on a few different factors. Primarily, those factors are the size, flow, and amount of use that each grease trap has. Whatever your scenario, we’ll be able to set up a schedule for your business’s needs.

Care and Maintenance: Treating Your Restaurant’s Grease Trap Right

A question many restaurant owners have is how often a grease trap really needs to be cleaned. Unfortunately, there’s no true rule of thumb. Depending on your kitchen’s size, type, and productivity, you’ll need a very different cleaning schedule from the restaurant down the street.

Still, there are quite a few things you can do to ensure your grease trap doesn’t get full too quickly. Best practices include minimizing the solid food waste that goes down the drain, rinsing greasy dishes with cold water, and using biodegradable detergents for cleaning.

Even with the best care, setting a proactive maintenance plan is still a smart idea. Overfull traps can quickly become disasters, requiring much more expensive clean-ups and even steep fines.

When cleaned and cared for properly, grease traps are invaluable assets to commercial kitchens that keep the pipes from being clogged up with fats, oils, and greases. However big or small the model, though, the general method that they employ to separate water from FOG liquids remains the same. DAR PRO Solutions offers professional services for cleaning them, since such a step becomes inevitable when dealing with the grimy side of culinary preparation. The grease might be slippery, but our professional process ensures that the service you get is anything but.

Darling Ingredients Canada is an expert in preventative grease trap cleaning and maintenance. Our comprehensive program will keep your trap functioning and compliant. Reach out to a representative today and find out how your business can benefit from our grease recycling program Call us at (800) 263-0302

Contact Sales

For customer service inquiries call our toll free number (800) 263-0302

By submitting this form I agree to the privacy policy including the usage of contact details to contact me for marketing purposes.