Laying the Groundwork

Grease traps are used to prevent sewage blockages and nearly every commercial kitchen is required to operate and maintain one. Cooking, baking, frying, dish washing, and really any culinary operation can produce fats, oils, and greases (FOG) that should not go down the drain. That’s where grease traps come in handy.

It is impossible to prevent all FOG materials from getting washed away in the kitchen and finding their way down the drain, even with procedures in place to minimize the number of FOG materials that are going into the sink. Fortunately, grease traps exist and are used for this very purpose.

Trapping and intercepting the FOG material before those greasy culprits make their way to the main sewer is a grease trap's only job. Depending on the nature of the job, grease traps vary in size and flow, and can be located anywhere from directly under the sink to under the parking lot.

Despite the fact that the job may seem simple, there are a wide variety of options when it comes to sizes, models, and efficiencies a grease trap can have. It is important to consult both local commercial kitchen regulations in your area and manufacturing professionals when choosing the right grease trap for your restaurant. The needs of each kitchen are different and, from province to province, the laws regarding the placement and size of the grease trap may change.

How Does a Grease Trap Work?

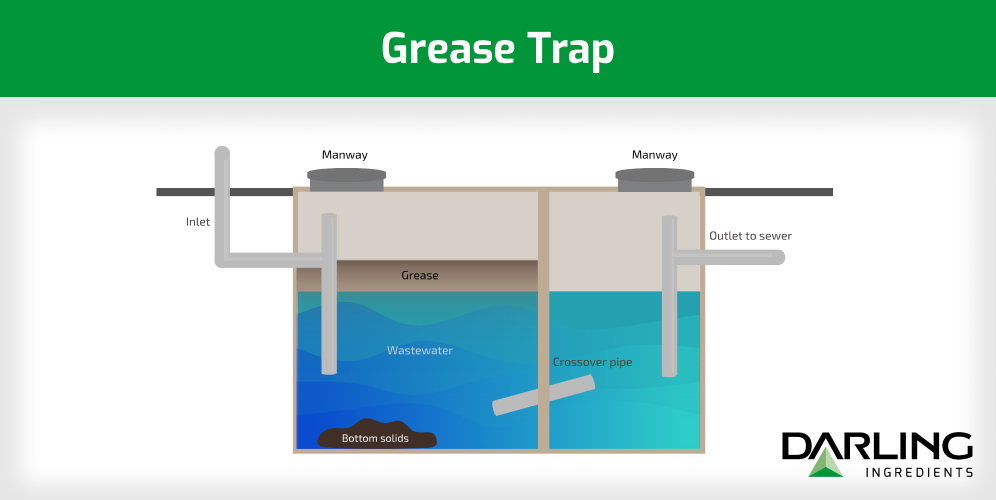

It is easy to quickly become confused when various different terms are tossed around, but rest assured that the same basic method is used in the operation of all grease traps. To remove FOG material from water, grease traps rely on utilizing the difference in density between the water and the grease.

It’s likely you’ve already seen this difference in action. Have you ever shaken up a bottle of tasty salad dressing made with both balsamic vinegar and oil? Then you know the two don’t stay mixed for long, even with vigorous shaking. The oil and vinegar parts always separate stubbornly into their own layers. Grease traps are designed to use this inevitable separation to your advantage.

With the knowledge that fats, oils, and greases will always rise to the surface when in water, using a tube to dip below the water’s surface can pull out the water that has separated from FOG liquids. Sludge and other non-FOG food waste will then quickly sink to the bottom.

While it may not be the most appetizing to compare salad dressing to liquid waste from the kitchen, the basic premise between the two is the same.

Is There a Difference Between a Grease Interceptor and a Grease Trap?

The term “grease trap” is often used by people to describe any type of technology that stops FOG material from causing problems, but the term does have a more specific definition. When you are purchasing a grease management system for your restaurant, it is helpful to be aware of some slight variations.

Fortunately, there are only two major distinctions: grease interceptors and grease traps. Grease interceptors have a flow greater than 50 gallons per minute, while grease traps have a flow of less than 50 gallons per minute. Thankfully, that is the main difference in classification between the two.

As you noticed, this definition does not necessarily determine size, but rather speed. The actual size of the grease interceptor or trap can vary, and the flow is the determining factor as far as the naming conventions go. Determining which one is right for a restaurant is a case-by-case basis that depends on different municipality guidelines.

Cleaning

How does a commercial grease trap work? You know the answer to that one now, by doing all the dirty work for you. But grease traps require periodic cleaning themselves too in order to perform at their best. To keep the technology working right, it is essential to empty them of grease and sludge regularly.

Even though some FOG material may decompose naturally, that process is too slow to be efficient, so it is important to clear it all out every once in a while. The frequency of your grease trap cleaning is determined by a few factors. Size, flow, and the amount of use each grease trap has are the primary determining factors.

Make sure you partner with a reliable grease trap cleaning business that will empty it on a regular basis.

How to Ensure Your Grease Trap is Properly Maintained

Being a restaurant owner comes with many questions, including how often a grease trap actually needs to be cleaned. Unfortunately, there is no one answer to this question. Your cleaning schedule will vary depending on the kitchen size, type, and productivity and will most likely be different from the cleaning schedule of the restaurant down the street from you.

No matter the schedule, there are still quite a few things you can do to ensure your grease trap doesn’t fill up too quickly. Rinsing greasy dishes with cold water, using biodegradable soaps for cleaning, and minimizing the solid food waste that goes down the drain are some of the best practices to use.

Setting a proactive maintenance plan is still a smart idea, even with the best care. Grease traps can overfill extremely quickly and become huge disasters that require expensive clean-ups. Overflowing grease traps may even result in steep fines. It’s best to avoid that altogether.

When your grease trap is properly cleaned and cared for, it will keep the pipes from becoming clogged up with FOG material and are invaluable assets to any commercial kitchen. The method of how they separate FOG liquids from water remains the same, regardless of the size and type of grease chosen.

Make Sure You’re Taking Care of Used Cooking Oil, Too

Grease can be a messy and slippery element of restaurant operations, but it doesn’t have to be.

Regular upkeep and cleaning of your kitchen equipment, including your grease trap, can help keep things running smoothly and cleanly. Additionally, it’s vital that you dispose of all of your used cooking oil (UCO) properly.

Darling Ingredients Canada can help you do just that, with little to no effort required on your part.

Darling Ingredients has a wide variety of used cooking oil containers and collection services to fit the needs of any restaurant. All that oil and grease needs to go somewhere when it’s no longer usable, and as established earlier, you definitely don’t want it to be dumped down the drain or put in the trash with other waste. Darling Ingredients has UCO systems that make disposal easy and safe along with service technicians who come pick it up on your schedule.

Scratch something off your do-to list and call Darling Ingredients today at 1-800-263-0302 to responsibly ditch that spent cooking oil you’re no longer using.

Contact Sales

For customer service inquiries call our toll free number (800) 263-0302

By submitting this form I agree to the privacy policy including the usage of contact details to contact me for marketing purposes.